Types of Forklifts

Types of Forklifts

Laborers rely on forklifts to allow them to perform heavy-duty tasks on time. From the lightest to the heaviest of loads, forklifts aid in various industries, including retail, logistics, auto and food. However, it can be overwhelming to choose the right forklift for the job you need to finish with so many classes and functionalities.

From the most common forklift types to identifying key forklift specifications, there is a lot to consider. Use this in-depth guide to learn about the various types of forklifts and the purposes they serve. We want you to confidently find the forklift most suitable for the job you need to complete.

Function vs. Class

When choosing the right forklift, it is essential to understand the difference between function and class. The Occupational Safety and Health Administration (OSHA) determines the classification of each forklift based on its engine and tire type. This disburses forklift models into seven different classifications, with each class offering its benefits and uses. Choosing a forklift is ideal for determining which class will deliver the best performance for the specific workload at hand.

Within those classifications, forklifts vary in their functionalities. Just because two forklifts are in the same class does not mean they can perform the same tasks. One forklift may have a higher weight capacity than another and still be placed under the same classification. Consider the following two examples of Class I forklifts:

- A 3-Wheel Electric forklift with a weight capacity of a few thousand pounds should be easy to maneuver by drivers, thanks to its tight turning radius. They are ideal for working in crowded warehouses and production lines and are often used in the food and beverage industries.

- A 4-Wheel Electric forklift with a much larger capacity can operate with heavier loads, such as building supplies. However, it is not as agile due to its much larger size in both frame and battery and the extra fourth wheel.

While both the 3-Wheel Electric forklift and the 4-Wheel forklift are placed under Class I: Electronic Motor Rider Trucks, it is evident that they are two very different models in functionality. Light manufacturing will typically not require something as heavy-duty as a 4-Wheel Electric. On the same token, a 3-Wheel Electric will not manage the same heavy-duty tasks as a 4-Wheel Electric.

When choosing the appropriate forklift, attention to detail for class and function can help narrow down the selection and find the perfect option.

How Many Types of Forklifts Are There?

There are dozens upon dozens of various models ranking in several classes and offering specific functions. No matter how big or small the job is, there is guaranteed to be a forklift in existence to assist with getting it done.

Different Classes of Forklifts

As previously mentioned, there are seven different classifications to categorize forklifts. The engine size and type of tire determines the class. Understanding the classifications can help tremendously when beginning the search for a forklift.

Electric Motor Rider Trucks

Forlifts that fall under this class are the most commonly used forklifts across numerous industries. This class offers an array of choices, including:

- 3-wheel electric

- 4-wheel electric

- Stand-up rider

- Outdoor electric pneumatics

- High-capacity forklifts

Electric Narrow Aisle Trucks

These types of forklifts work perfectly for tight spaces. Warehouses that have incredibly tight areas due to narrow aisles can benefit greatly from this class. Forklift model options in this class include:

- Order pickers

- Reach trucks

- Articulated forklifts

- Pivoting-mast forklifts

Electric Motor Hand or Hand-Rider Trucks

Mobiles that fall under the Class III category are technically not considered forklifts. They are generally referred to as lift trucks. Various choices can be found in Class III, such as:

- Material lifts

- Hand pallet jacks

- Electric walkie pallet jacks

- Walker/Rider pallet jacks

- Center-controlled pallet jacks

- Paper roll handlers

- Walkie stackers

Internal Combustion Engine Trucks-Cushion Tires

Internal Combustion Engine (ICE) trucks offer many benefits but are also only suitable for certain environments. Whereas you can use other forklifts and lift trucks in food and pharmaceutical warehouses, these forklifts are limited due to the noise and exhaust they create. Still, advances in emissions technology are making them more viable. Forklift models available in Class IV include:

- 3,000 to 15,000 lb cushion forklifts

- High-Capacity cushion forklifts (15,000 to 110,000 lbs.)

Internal Combustion Engine Trucks-Pneumatic Tires

As previously stated, IC trucks are limited in the industries in which they can be used. However, the Class V models offer benefits that the other classes do not. While other forklifts and lift trucks are restricted to indoor and smooth-floor environments, Class V models can also handle outdoor work. You can find the following models in the Class V category:

- 3,000 to 17,500 lb. pneumatic forklifts

- High-Capacity forklifts, including yard trucks, marina forklifts and container handlers

Electric and Internal Combustion Engine Tractors

Typically used to transport luggage carts at airports and working on assembly lines, Class VI trucks can pull a lot of weight. Models that fall under Class VI are generally known as:

- Tow Tractors

- Tuggers

Rough Terrain Forklift Trucks

You will often see mobiles in this class on construction sites, farms and even military applications. Popular models of machinery in this class include:

- Telehandlers

- Off-road forklifts

- Truck-mounted forklifts

- Tractor forklifts

- Wheel loaders

- Skid steers

Different Functions of Forklifts

Forklifts in different classes offer a variety of different functions. Some operate for light-duty work, while others carry some of the heaviest loads possible. After deciding the class of forklift or lift truck is the most appropriate for your needs, evaluate the different functions of each piece of machinery within each class. This will help pinpoint the most suitable option for any job that may be at hand.

Class I Functions

Ideal for moving items such as pallets on smooth driving surfaces, they offer many benefits as they:

- Emit zero fumes.

- Are much quieter than other forklifts.

- Sometimes have a cushion or pneumatic tires.

- Offer stand-up and sit-down model choices.

- Are excellent for unloading and loading trailers.

Class II Functions

These narrow forklifts provide operations with ways to maximize their storage space in close quarters. Because you can operate them in such a minimal amount of space, they generally:

- Help operators when handpicking materials.

- Assist with reaching high areas.

- Fit in spaces where standard-size forklifts cannot.

Class III Functions

These lift trucks are designed for maximizing horizontal transportation, whereas forklifts focus on vertical transportation. Lift trucks in this class:

- Hoist materials are too heavy for humans.

- Transport pallets from one spot to another.

- Assist with stacking.

- Offer ride-on and walk-behind options.

- Come in unique designs for particular purposes.

Class IV Functions

Because they do not run clean via electric engines, they emit fumes and are therefore limited to performing within specific industries and environments. However, they do make good options for:

- Warehouses without enough space for charging stations.

- Operating on loading docks and storage areas.

- Compatability with special attachments for various purposes.

- Lifting heavy loads without using a larger size.

Class V Functions

These models can take the workload outside as well as inside. This makes them an ideal choice for job sites that require:

- Light or heavy lifting indoors or outdoors.

- Tires built for running across rough terrain.

- Cabs for operators to remain protected from outdoor elements.

- Lifting and transporting oversized workloads.

Class VI Functions

Class VI models operate with either an electric engine or an IC engine, making them a viable option for various industries. These models are typically known for their tugging abilities as well as:

- Towing loads as opposed to lifting.

- Having an extremely tight turn radius.

- Quicker speed and operation time.

- Maximum capacities of over 50,000 lbs.

Class VII Functions

Thanks to their heavy-duty suspension and rugged-terrain tires, Class VII models are ideal for outdoor work. These models boast features such as:

- Lifting huge capacities.

- Mounting onto trailers for easy transportation.

- Transporting heavy loads across rugged and muddy terrain with ease.

- Intensive height reach.

- Having the capability to work with different attachments.

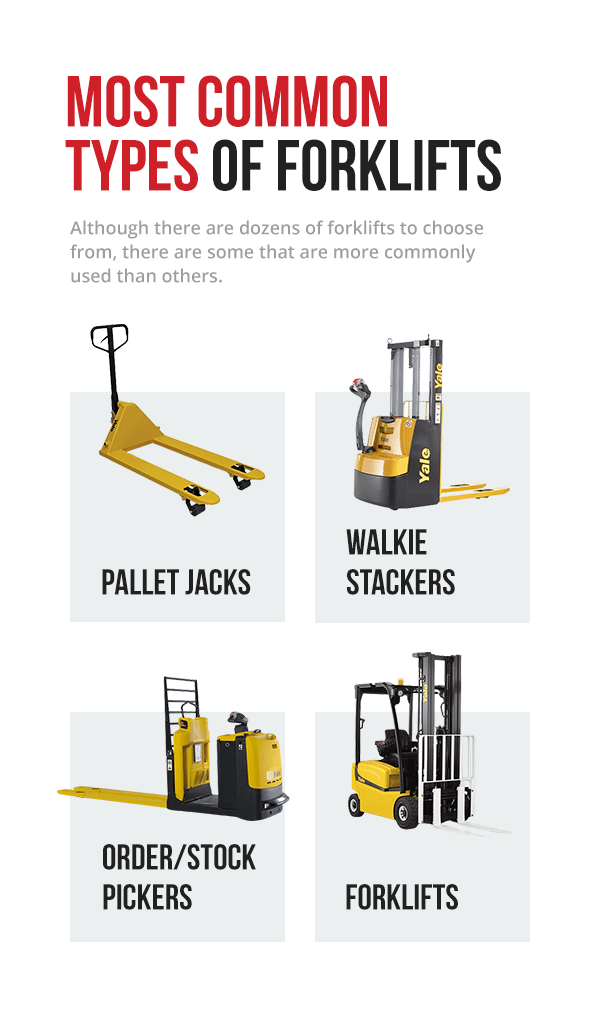

Most Common Types of Forklifts

Although there are dozens of forklifts to choose from, there are some that are more commonly used than others. Take a look at some of the different forklift models that are more widely utilized across various industries and provide excellent functionality.

Pallet Jacks

A simple piece of machinery, the manual hand pallet jacks are quite reliable. You can use them in small spaces to lift and transport heavy loads. They are an essential part of warehousing, logistics, freight handling and more.

As essential as the manual pallet jack to many industries, the battery-electric pallet jack offers the same maneuverability with added help from a battery. These forklifts reduce the risk of operator fatigue and injury by allowing operations to be done with buttons. A battery pallet jack can also handle more weight than its manual counterpart.

Walkie Stackers

Walkie stackers allow operators to lift and transport loads with the same capacity as an electric pallet jack. However, they can lift loads much higher, making them the perfect choice for stocking warehouse aisles. Additionally, they allow operators to walk behind them and control the functionalities from the side, which reduces the risk of accidental injury.

Walkie reach stackers offer the same benefits as typical walkie stackers. One of the most significant differences and advantages is that the tynes can reach forward and backward. This allows the pick-up and drop-off of loads onto shelving.

Order/Stock Pickers

Also used in warehousing and logistics, low-level order/stock pickers help select items at low levels. Individual quantities of items and stock are collected from large bulk storage areas to be sent out for fulfillment rather than moving entire pallets around.

In many bulk storage areas, inventory is up much higher than the average person can reach. Medium-to-high level order/stock pickers can be influential with retrieving and transporting items at low height levels, but they also have another advantage. These pickers allow the operator to safely reach high up into the storage racks to pull the needed items.

Forklifts

Counterbalance Forklifts are some of the most popular models. With tynes in the front and counterweights on the back, it can handle large weights without going too large in size. Electric units and IC units are available while they differ significantly in weight capacity limits.

Side-loader/Multidirectional Forklifts are ideal for managing heavy and long loads like timber and metal. Whereas the operator sits behind loads in other forklifts, the operator sits off to the side, allowing them to have a clear line of sight. They also have excellent maneuverability, and you can move them in narrow spaces.

Just as it sounds, you can use Articulating Narrow Aisle Forklifts in highly narrow spaces only 78″ wide. This is especially great for warehouses that have limited space and a lot of inventory. An articulating mast that works separately from the counterbalanced body can move left, right, and straight within an aisle, reducing the need to turn the entire unit constantly.

Key Forklift Specifications

There are essential specifications to pay attention to when choosing the function and class of any forklift. When making your final decision, consider the following questions::

- How heavy are the average loads that are transported?

- What is the typical height needed to lift each load?

- How wide are the aisles in which you will operate the forklift?

- Will you use the forklift mainly indoors and on smooth floors or outdoors on rough terrain?

- How much is in the budget compared to the required class and functionality?

It is also essential to understand these critical terms, what they mean, and how they relate to average loads:

- Forklift capacity: The measurement of how much any specific forklift can lift, which can vary widely. Know the average weight of loads during daily operations to ensure the correct weight-bearing forklift is selected.

- Load center: The basis for rating the load capacity of any forklift. The distance measured from the front vertical face of the forks to the load’s center of gravity. If loads vary from light to heavy-duty, always go by the heaviest loads.

- Dimensions and lift height: Be cautious of the dimensions and lift height of any potential forklift selection. Be aware of how much vertical and horizontal space is available for maneuverability. Always go by the maximum measurements for height and distances between aisles.

Having proper knowledge will help make the selection process of investing in the perfect forklift go a lot faster by elimination.

Contact Chicago Industrial Equipment for all your Forklift Needs

Chicago Industrial equipment is dedicated to connecting our clients with the perfect fit for any business or project they may have. Our extensive and top-of-the-line inventory will help maximize efficiency and productivity. Every piece of equipment we supply is carefully inspected and serviced in-house by trusted and certified technicians.

Please take a look at our online inventory to learn more about the forklifts we offer. As always, feel free to contact us with any questions. We are happy to help you select the right solution!